Something that was recently resurrected from my memory was the fact that I used to do training on master planning in Dynamics AX. When I started, it was on AX 2009, but then I moved to AX 2012 and Dynamics 365, too. Since the beginning of Microsoft’s ownership of Dynamics AX, there hasn’t been a ton of wholesale changes to the way master planning works. I’m going to start a blog series starting from the basics. It’s not going to be comprehensive, but hopefully it’ll be a good primer on what MRP is and how it kind of works. (If you want to see some of my past work, click here

How to learn master planning

Everyone learns differently, but this is my blog and I’m going to structure in the way that works best for me and has had some success in the past.

There’s two main ways that I learned this stuff and they’re both things I try to impart on people that attend my training courses. First, try to find an environment where you can test this functionality. The documentation is verbose, but not necessarily very clear how something practically works. I like to setup a little example scenario and work through how it works in a test environment to give myself a hands-on understanding of what’s really going on.

Secondly, start small. As you’ll begin to see, there’s a lot of moving parts in master planning. Item setup, calendars, vendors, warehouses: almost everything relating to inventory has an impact on master planning. The more variables you can remove from the equation allows you to isolate changes to see the repeatable impact that each of these changes has on your scenario.

Throughout this series, we’re going to try to adhere to these principals. I’ll make very small but intentional changes and scenarios in order to best illustrate the principles I’m discussing.

What is master planning in Dynamics 365 Supply Chain Management

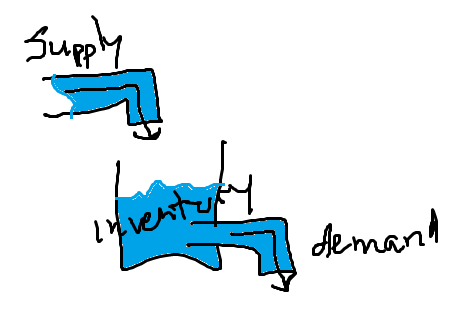

Master planning is a calculation engine that Dynamics 365 uses to determine if the existing on-hand inventory and planned upcoming inventory can satisfy the company’s demands. In this little math equation, the left-hand side can be simplied as “supply” and the right-hand side can represent demand.

Supply can be lots of things; on-hand inventory sitting in a warehouse, purchase orders that have been confirmed and are expected to be received at some point, production orders that have been created and are in-process (or still sitting there waiting to get started). Similarly, demand can be represented by sales orders, production order usage (if the item is a subcomponent in a bill of materials), or a transfer order to another warehouse. These aren’t exhaustive, but they serve to illustrate the point.

Think of your inventory as a bucket with water in it. On one side of the bucket, there’s a hole with water leaking out of it (the demand) and on the other side, there’s a hose putting more water in (supply.)

When demand outstrips supply, the bucket empties. MRP’s purpose is to make sure the bucket never runs out. If master planning looks at the supply and realizes there’s too much demand to be satisfied by the existing supply, that’s where the magic happens. In this case, master planning’s next step is to create what are referred to as “planned orders”.

What’s a planned order?

A planned order is MRP adding another hose to the top of the bucket – it’s a suggestion indicating that MRP thinks you need to get more inventory to satisfy the demand. There are several types of planned orders; planned transfer orders, planned production (or batch) orders, planned Kanban orders, and planned purchase orders. Depending on the way the item that’s being planned for is setup, master planning will choose one of these orders and create it.

An important point here, though, is that a planned order is truly just a suggestion. All the planned orders in the universe aren’t going to help you get your inventory back in-line. This is typically when a human comes in. Someone needs to review these planned orders and “confirm” them into actual orders. For example, when master planning generates a planned purchase order that says you need to buy 100 widgets and have them delivered at the end of next month, a planner has to come in and turn that into an actual purchase order for 100 widgets from Manufacturer A and let the manufacturer know.

Now, I’m sure you’re all sitting on the edge of your seats and wondering “well, how does MRP determine how big the order needs to be?!” and “will it make sure I have my inventory available on time?!?” We’ll get to that in some of the next posts.

Looking for more? Check out my master planning resources page.

Leave a Reply Cancel reply